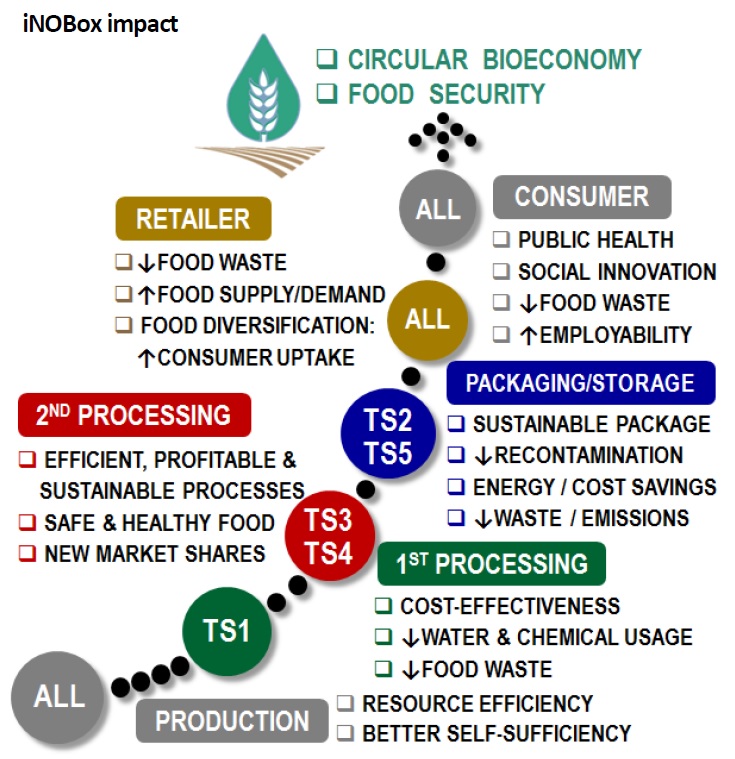

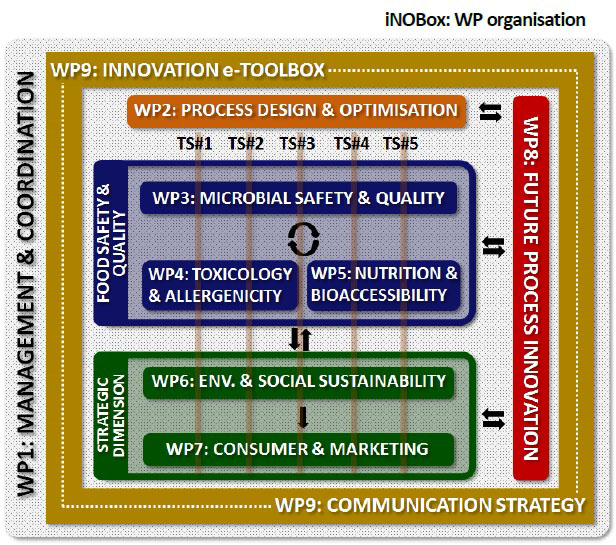

Teaming up with key industry and market players, iNOBox main goal is to integrate in the Norwegian food industry more efficient, profitable and sustainable processing, securing the supply of safe, high-quality and nutritious foods.

Innovative food processing technologies can help to meet the demand of sustainable and affordable healthy diets for a growing and aging population. Through cross-disciplinary research, iNOBox will greatly advance the current knowledge on innovative technologies, such as cold plasma, pulsed electric fields, ultrasounds, UV-light, high-pressure processing and microwaves. Safer and healthier foods resulting from innovative processing will improve the public health system through reduced prevalence of food allergy, diet-related diseases, food recalls and associated health/social costs. Consumers will also benefit from reduced food waste through the extended shelf life of innovative foods. Furthermore, iNOBox outcomes will improve energy savings in the food sector.

To ensure the successful implementation of innovative processes, food producers must be aware of their benefits, suitability for different products/applications, as well as scientific, technical and regulatory aspects. iNOBox aims to develop a web-based innovation toolbox to help food industry make informed decisions on process innovation, overcome bottlenecks to market and ensure innovative products reach the consumers. The e-toolbox will be built upon durable projects outputs and external data sources, enabling effective knowledge sharing of iNOBox outcomes.

The iNOBox team is led by Nofima and includes national and international research and industry partners. The project provides training opportunities to young scientists (2 PhDs and 2 Postdocs). Project partners: Nofima (NO), Veterinærinstituttet (NO), Østfoldforskning (NO), University of Liverpool (UK), Campden BRI (UK), University of Zaragoza (ES), TNO (NL), Bamagruppen (NO), Den stolte hane (NO), Findus Norge (NO), Fjordland (NO), Matvarehuset (NO), Fjordkjøkken (NO), HOFF (NO), MatBørsen (NO), Advanced Microwave Technologies (UK), ELEA-Technology (DE), Hiperbaric (ES/US), UV Technology (UK).

The Toxinology Research Group at the Norwegian Veterinary Institute is leading Workpackage 4, which is dedicated to assess aspects of toxicology and allergenicity of innovative agri-food products. By evaluating consequences of changes in the food metabolome and immune reactivity of food proteins for consumer health, the food safety of the novel products will be assessed.

Novel technologies are central to the project. Six innovative food processing technologies (IPTs) have been selected for the project: Cold plasma (deactivation of bacteria by rinsing fresh berries and vegetables in water with cold plasma can prolong shelf-life with up to 2 weeks); UV light (deactivation of bacteria in packaged food with UV-C light); Ultrasound (treatment of food products for increased shelf-life); Pulsed Electric Fields (destruction of microbial cells in different food including milk, chicken, fruits, vegetables, juices; additionally, increase of food quality characteristics such as improved cutting and faster frying times for potatoes); Microwaves (rapid heating of food); High pressure processing (deactivation of bacteria and increase of shelf-life due to processing of food with use up to 6000 bar; potential reduction of allergenicity).

In iNOBox we will document the effects of these technologies on selected foods and processes in the food industry.

Project participants at NVI:

Christiane Kruse Fæste

Silvio Uhlig

Oscar Daniel Rangel-Huerta

Current status at NVI (WP4):

- Sample preparation and workflow for metabolomics analyses established.

- Differently processed chicken samples analysed by metabolomics and statistical analysis completed. Results will be presented in a manuscript (currently in preparation).

- Immunological analysis of differently processed egg samples planned.

Publications and presentations

- Rangel-Huerta, O.D.; Ivanova, L.; Uhlig, S.; Sivertsvik, M.; Sone, I; Fernández, E.N.; Fæste, C.K. Impact of plasma-activated water treatment on quality and shelf-life of fresh spinach leaves evaluated by comprehensive metabolomic analysis, Foods, 2021, 3067.

- Rangel-Huerta, O. D.; Uhlig, S.; Ivanova, L.; Dang, T. T.; Rode, T. M.; Noriega Fernández, E.; Fæste, C. K., Metabolomics workflow for quality control of differently-processed pre-cooked chicken fillets. Food Chem. 2022, 370, 131006.

- Rangel-Huerta OD, Ivanova L, Uhlig S, Rode TM, Noriega E, Faeste CK. The impact of a modified atmosphere packaging method in cooked chicken breast: a metabolomics investigation. Poster at Nordic Metabolomics Conference 2020, 27.-29.10.2020.

Funding: NFR Bionær (NFR 281106) 2018-2022

Read more about iNOBox